The system works with Hopper Dryer and sets beside the injection machine to collect the degraded material and scraps produced while injection molding. The regrinding is then conveyed by the blower to the mixing chamber with virgin material proportionally and melt in the plastic-melting chamber. Therefore, the waste materials are reclaimed right before their characteristics change so as to keep the quality, low waste and production cost.

Features:

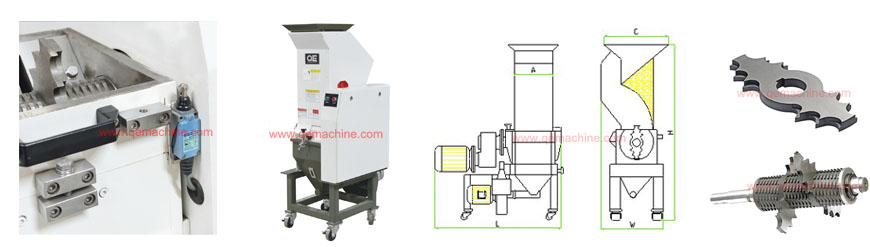

•Low speed operation, low level of noise low power consumption.

•Installed with a high quality gear motor. Machine’s function is stable, long life-span, the transmission torque is large.

•Special design of the crushing blade let the crushed bits are in even size and minimized the dust generated during operation.

•Blade is made of imported material, high efficiency in operation.

•Motor is installed with overload protective device, connected to the power switch to ensure the machine and controller’s safety.

•Equipped with auto-loading system to make sure the crushed bits are not be polluted, decrease work load, and increase efficiency.

•The contour of the QS-25 is artistic, a strong structure, easy to install, easy and quick maintenance.

•The base is installed with wheels, enable to move around.

•CE safety standards

Specifications:

Type | QS2530 | QS3030 | QS3040 | QS3050 | |

Motor Power | Kw | 1.1 | 1.5 | 2.2 | 4 |

Rotating speed | Rpm | 20 | 20 | 20 | 21 |

Material of blades | SKD-11 | SKD-11 | SKD-11 | SKD-11 | |

Quantity of Rotating Blades | Pcs | 2 | 2 | 3 | 3 |

Quantity of Fixed Blades | Pcs | 3 | 3 | 4 | 4 |

Edge Blades | pcs | 6 | 6 | 6 | 8 |

Cutting chamber | mm | 250×300 | 300×305 | 305×415 | 380×480 |

Instantaneous recycling system | √ | √ | √ | √ | |

Blower conveying device | √ | √ | √ | √ | |

Full-receiver alarm device | o | o | o | o | |

Weight | Kg | 240 | 270 | 320 | 750 |

Dimensions | mm | 900×430×1420 | 1040×480×1480 | 1200×480×1500 | 850x610x1550 |

We reserve the right to change specifications without prior notice.

Notes:

1)"√"Stands for standard. "o" stands for optional.

2)SKD11 is steel grade of Japanese JIS standard.

4)To avoid plastic from sticking to the blades, all materials should be crushed at normal temperature.

5)Power supply: 3¢,110/220/230/380/400/415/440/460/480/575VAC,50/60HZ.